Transfemoral Prostheses

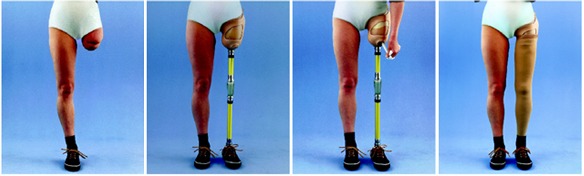

Transfemoral amputations may be added to modular or exoskeletal systems. Modular transfemoral prostheses are an obvious illustration of the advancements gained in prosthetics. The fitting of prosthetic sockets, socket materials, and industrially constructed prosthetic components have all seen significant advancements. The use of thermoplastic materials and lamination resins to make transfemoral sockets has gradually superseded the usage of wood.

The design and manufacture of sockets can be done with the aid of a computer. Using specialised software, an optimistic model is created based on measurements of the patient’s residual limb. Making a socket for thermoplastic testing requires this.

Numerous new prototypes have been added to the extensive range of knee joints, prosthetic feet, and adapters. Modules are utilised in particular for senior patients to meet their needs with a high level of stability and comfort.

Flexibility during the stationary face and management of the range of motion during the swing operation are additional requirements that the various knee joints must satisfy. Today, electronic regulators assist users in walking by varying resistance at various rates, while hydraulic stance face controls assist users in moving downstairs step by step.

The residual limb function, therapy goals, patient profile, and fitting experience all play a role in determining which knee joint goes in the prosthetic foot. The foam coating on the modular prosthesis gives it a primarily natural appearance. The opposite leg’s contour is developed specifically for it.

Many youthful, active patients entirely remove the aesthetic covering in favour of the prosthesis’ sporting appearance. With the aid of properly modified prostheses, they are able to achieve exceptional results in handicapped sports.

This has demonstrated success following surgical recovery. The thermoplastic pre-shaped socket is directly shrunk into the shapes of the residual limb by the application of hot air.

Before the final prosthesis is created, an interim prosthesis is worn. Additionally helped is the choice of the necessary definitive prosthesis.

The adoption of tilting socket design is frequently the only option for treating very short transfemoral residual limbs. A lock secures a hip joint to the prosthetic socket distally. For sitting, this can be deactivated.